Boiler Condensate Pipe Guide: Prevent Winter Breakdowns

- Back Office

- Dec 7, 2025

- 5 min read

It’s a cold winter morning, and you wake up to find your house is freezing.

The heating isn't working, and the boiler is showing a fault code. This is a frustrating and stressful situation for any homeowner, and surprisingly often, the cause is a small, overlooked component: the condensate pipe.

We understand how worrying it is to be left without heating, especially during the coldest months. This pipe plays a vital role in your modern condensing boiler, but if it's not installed or maintained correctly, it can lead to a complete system shutdown.

In this guide, we'll walk you through everything you need to know about your boiler's condensate pipe. We’ll explain what it does, why regulations are so important, and how you can prevent common problems like freezing. Our goal is to give you the knowledge and peace of mind that your home will stay warm and safe, all winter long.

What is a Boiler Condensate Pipe?

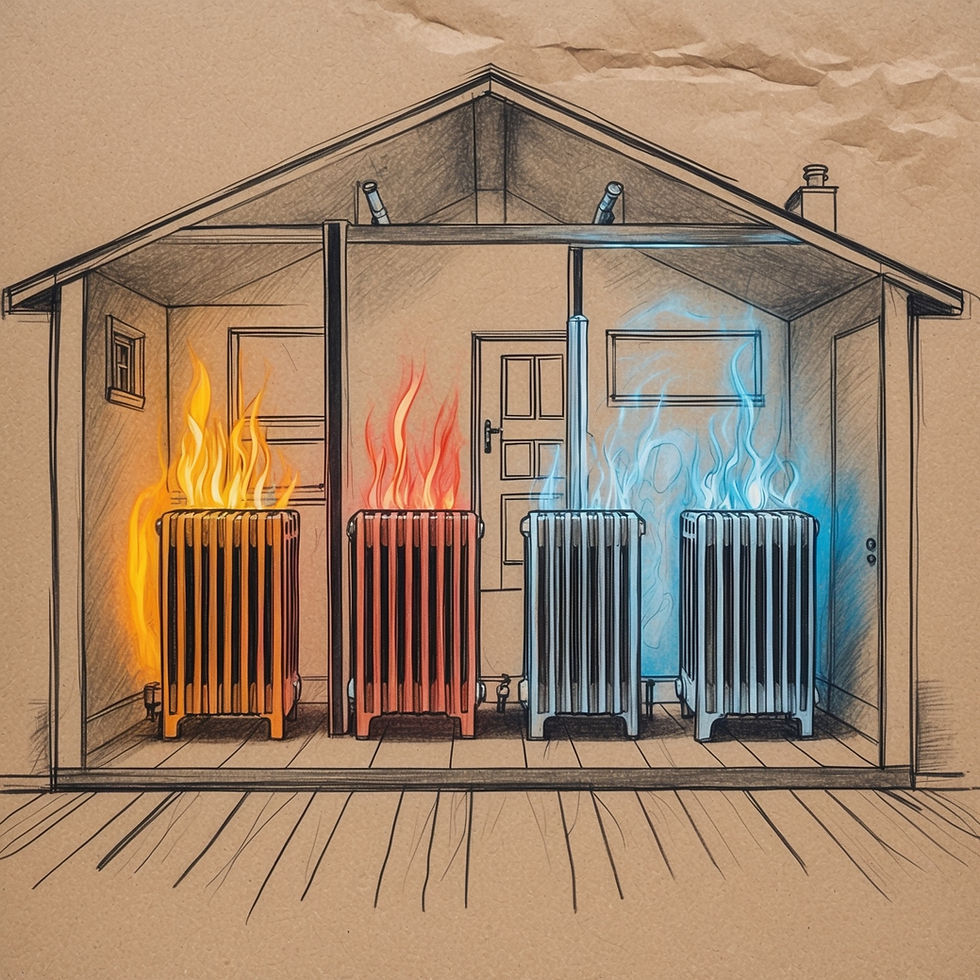

If your boiler was installed after 2005, it is most likely a high-efficiency condensing boiler. These systems are designed to be much more efficient than older models by capturing and reusing heat that would otherwise be lost through the flue (the pipe that carries exhaust gases outside).

As these hot gases are cooled, they produce a small amount of acidic water, known as condensate. This is where the condensate pipe comes in. Its job is to safely carry this liquid away from the boiler and dispose of it into your household's wastewater system. A typical condensing boiler can produce around two litres of condensate per hour while it's running.

The pipe itself is usually a small plastic pipe (often white or grey) that runs from your boiler to a drain. This might be an internal drain, like a kitchen sink waste pipe, or an external drain outside your property.

Why are Condensate Pipe Regulations Important?

You might wonder why there are specific rules for something as simple as a small pipe. Building regulations for condensate pipes exist for very important reasons, all centred on keeping your heating system running safely and efficiently.

1. Preventing Freezing and Boiler Shutdowns

The most common issue with condensate pipes is freezing. If the pipe runs externally and isn't properly protected from the elements, the water inside can freeze during a cold snap. This creates a blockage, and your boiler's sensors will detect that the condensate cannot drain away. As a safety measure, the boiler will shut down, leaving you without heating or hot water. Incorrectly installed condensate pipes have been a leading cause of boiler breakdowns for over a decade.

2. Ensuring Safety and Preventing Corrosion

The condensate produced by your boiler is slightly acidic. If it's not disposed of correctly, it can cause damage over time. Discharging it into the wrong type of drain or onto the ground can lead to corrosion of materials and harm to the environment. Regulations ensure the condensate is neutralised where necessary and routed into a suitable foul water drain, protecting your property and drainage system.

3. Avoiding Costly Future Repairs

Following the regulations from the start is about more than just compliance; it's about preventing future problems. A properly installed condensate pipe is far less likely to freeze or cause blockages, saving you the stress and expense of an emergency call-out for a non-working boiler. It’s a small detail that makes a big difference in the long-term reliability of your heating system.

How to Check if Your Condensate Pipe is Compliant

Understanding the rules can help you identify if your own system is set up correctly. The official guidance from industry bodies like the Heating and Hot Water Industry Council (HHIC) and British Standards (BS 6798) sets clear preferences for installation.

The Best Practice: Internal Drainage

Whenever possible, the condensate pipe should terminate at an internal "gravity discharge point." This means connecting it to a waste pipe inside your home, such as:

An internal soil stack (the large vertical pipe that carries waste from toilets and sinks).

A kitchen or bathroom sink waste pipe.

A washing machine or dishwasher waste pipe.

Running the pipe internally is the preferred method because it is protected from cold outdoor temperatures, virtually eliminating the risk of freezing.

When an External Pipe is Unavoidable

Sometimes, it’s not practical to connect the pipe to an internal drain. In these cases, specific rules must be followed to minimise the risk of freezing:

Pipe Diameter: The external section of the pipe must have an internal diameter of at least 32mm (a noticeable increase from the standard 21.5mm pipe used internally). A larger diameter means it takes much longer for the pipe to freeze solid.

Pipe Insulation: The external pipework must be insulated with high-quality, waterproof, and UV-resistant material. This "pipe lagging" acts like a jacket, protecting the pipe from the cold.

Termination Point: The pipe should terminate below the grid of an external drain but above the water level to prevent backflow. It's also recommended to cut the end of the pipe at a 45-degree angle to help the condensate drip away more effectively.

If your external pipe is narrow and uninsulated, it is not compliant and is at a high risk of freezing.

Keeping Your Home Warm: Preventing a Frozen Condensate Pipe

Waking up to a cold house is an experience we want to help you avoid. Here are some practical steps you can take to protect your boiler this winter.

Check Your Installation

Take a look at where your condensate pipe runs. If it goes outside, check if it meets the requirements. Is it wider than a standard internal waste pipe? Is it covered in thick, weatherproof insulation? If not, it's a good idea to get it upgraded. This is a relatively small job that can save you a huge amount of trouble.

Add Insulation

If your pipe is the correct size but lacks insulation, this is something that can be easily fixed. You can purchase the correct pipe lagging from most DIY stores. Ensure it's waterproof and secured properly to cover the entire length of the external pipe.

What to Do if Your Pipe Freezes

If the worst happens and you suspect your pipe has frozen, you may see a specific fault code on your boiler's display (check your manual for details). You can often resolve this yourself without needing an engineer.

Locate the Pipe: Find the plastic pipe leading away from your boiler and identify the section that runs outside.

Warm the Pipe: Use a hot water bottle, a microwaveable heat pack, or a cloth soaked in warm water to gently thaw the blockage. Never use a blowtorch or boiling water, as this can damage or crack the plastic pipe.

Reset Your Boiler: Once the blockage has cleared and water can flow freely, you should be able to reset your boiler and get your heating back on.

If you don't feel comfortable doing this, or if the problem persists, it's always best to call a professional.

Let Us Give You Peace of Mind

Understanding boiler regulations can feel technical, but we're here to make it simple. At Boilers2Ac LTD, your family's warmth and safety are our top priorities. We believe in getting the job done right, ensuring every installation not only meets but exceeds the required standards for safety and reliability.

If you're unsure whether your boiler setup is compliant or if you're worried about the risk of a frozen pipe this winter, please reach out to us. We can provide expert advice, inspect your system, and carry out any necessary upgrades to give you complete peace of mind.

Don't wait for a cold snap to find out your boiler is at risk.

Contact us today for a friendly, no-obligation consultation.

Comments